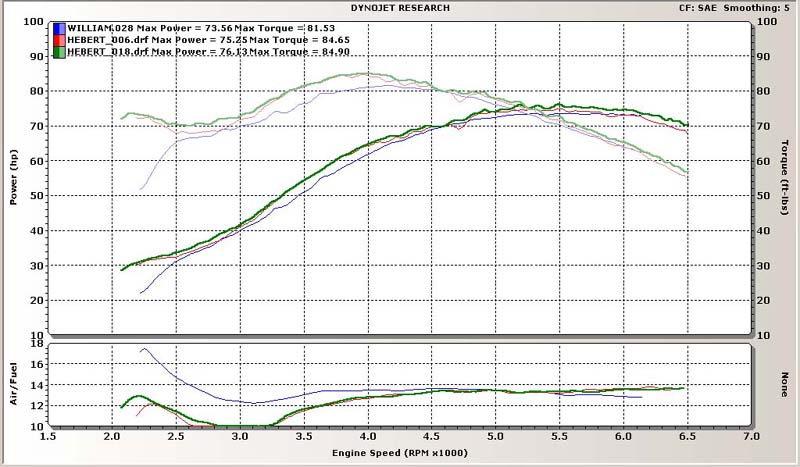

| DYNO Results / Run028SAE

techbill Run 004 Run 016 Run 028 Run 028 SAE DynoOperator DifferentDay Rejet.html Home admin@techbill.net admin@techbill.net |

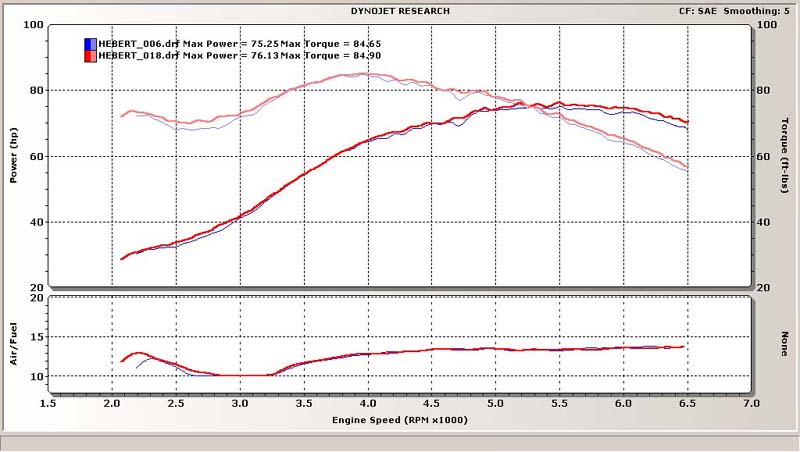

Here we rejetted the carb. Run006 is the new baseline from our initial run. #045 slow jet, #205?? main jet. No shims. Thunderheader and Force Winder Air cleaner.

Run 018 is the final run after the reject. We kept the #45 slow jet and put the stock #195 main jet back in. We also added three (3) shims under the needle. Hey looks the same! Even the Air/fuel ratio looks the same. So why did I rejet?

This is why one needs a good dyno dude. All the Full power runs that were done before showed decent Air/Fuel ratio's and nice Peak Torque/Power numbers. That was with stock #42 slow jet and stock #195 main jet.

But the bike ran hotter than hell, and pinged on warm days during take off. I had to get the RPM's above 2500 before I took off to avoid pinging. Riding around seemed okay.

When I put the thunderheader on we had to swap out the main jet from the #195 to the #205 (drilled out #200 unknown to me at the time). Bike ran the same dyno showed some better peak numbers, so I rode it that way for about six months.

What had been bothering me for a long time was that onone else on the XL-List had to run a #205 main jet, and all the advice was to use a #45 or #48 main jet. So I decided to swap the slow jet for a #45 and see what happened. I also finally drilled out the idle plug and set that to 2.5 turns from the original position of about 1.75 turns.

The key thing here was what the Air/Fuel ratio was doing under partial throttle. In order to do that on a Dyno you need a Dyno brake attached that will hold speed constand at different power levels. This way one can test with 1/8, 1/4, 1/2, and 3/4 throttle under load so the CV carb is working and see what the Air/Fuel ratio is.

Run 006 is our baseline full throttle dyno run. What we can't graph was the 16:1 to 18:1 air/fuel ratio at partial throttles! Talk about running lean!

Changing the setup gave us the same curves and numbers for the full throttle dyno runs, but the key here with the smaller main and shimmed needle is my partial throttle ratios are all in the "ideal" range. Somewhere around 12.5:1 to 14:1.

So here I have been advising people to get a good dyno tune. Little did I know that I didn't really have one, until I saw one done. So I got to go back and get a better dyno tune that took care of all the real world partial throttle settings and not just the Full throttle setting.

If you get your bike dyno tuned, I advise you to be there when it is done. Also ask if they have a "dyno brake" which is an electric brake on the dyno wheel which holds speed constant by varying the load. If they don't have a brake, they can't really do the partial throttle checks. Also watch them do the partial throttle checks and see the Air fuel ratios. We spend more time at 1/4 throttle than we do at full throttle.

The hard part is the dyno operator needs to be aware of the affects of where they place the O2 sensor in the exhaust. Moving the sensor around and show different readings, especially with something like a Thunderheader or a SuperTrapp exhaust.

I think, but don't know as a proven fact, that the O2 sensor could show false "Lean" readings but not false "Rich" readings. Generally the issue is any air drawn back into the exhaust due to reversion. That extra oxygen can burn any extra fuel that is in the exhuast system showing a correct or lean mixture. The O2 sensor needs to be rammed up the exhaust far enough that any ambient air drawn in doesn't affect the reading.

Below shows Run 028 done in January where the #205 main jet was put in, then Run 006, the August baseline with the #45 slow jet, finally Run 018 which is the #195 main jet and three shims.